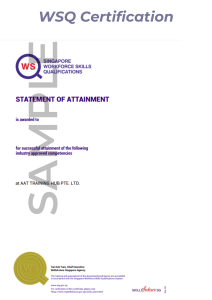

Certification

Upon fulfilling the course requirements with a minimum attendance rate of 100% and demonstrating proficiency in the assessments, candidates will be awarded a Certificate of Completion from AAT Training Hub, and a nationally recognised WSQ Statement of Attainment